capsule filling machine working principle

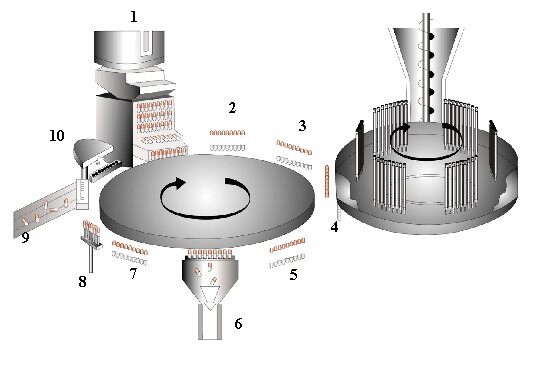

Even though the process seems simple and straightforward any failuremalfunction in any of the tamping pins may cause serious loss high rate of capsule rejection. The sensor in the powder ring controls the spiral feeding rod above it the addition of the powder to make the powder ring constant height intermittently rotating at the measuring plate five groups of tamping rods successively consolidate the powder in the measuring plate hole and in the filling station push the medicine column into the capsule After that we will enter the.

Tamping Pin Type Capsule Filling Machine Working Principle

Ejection of filled capsules.

. Rejoining of caps and bodies. Working principle of soft capsule filling machine and operation method Oct 07 2019. The capsule before sent for delivery needs to be properly processed and filled with the help of a capsule filler.

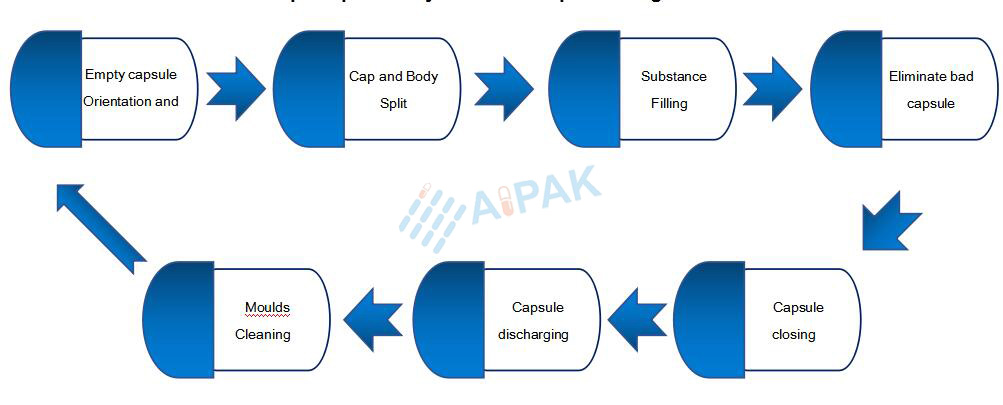

The capsules are rectified caps and bodies are separated active pharmaceutical ingredients API is filled wasted capsules are rejected capsules are locked in. Every machine has its own working method. The Working Principle of Trustar Dosator Capsule Filling Machine.

Regardless of the type and model of your auto or semi-automatic capsule filling machine a vacuum system is vital. This can be done manually or with the help of an automatic capsule filling machine. The positioning of colourless translucent capsules in the capsule filling tray.

This can be done either manually or by means of an automated capsule filling machine. Once the liquid matter is filled the corking unit is individually responsible for placing caps and lids on the packed vessels. Httpswwwcapsulemachinesin demostrating Capsule Filling Machine Working Principal which shows Functional Principle of Capsule Filling Process.

A dosator machine with two segments powder and capsule sections. The machine that can greatly improve production efficiency and reduce labor costs. The Working Principle of SaintyCo Dosator Capsule Filling Machine.

This can be classified as liquid pressure filling which means the liquid flows into the bottle based on its own weight. Dosing of fill materialformulation filling the bodies. Automatic capsule filling machine working principle.

- Thursday June 6 2019. In this station the upper and lower parts of the capsule body are separated by vacuum suction. Second the vacuum system separates the empty capsule to avoid damage.

These personal capsule filler machines allow people to fill their capsules with the necessary medication. Working Principle of Capsule Filling Machine. Automatic capsule filling machine is a fully automatic capsule filling machine with which capsule separation filling and locking can be done automatically.

The capsule filling machine works in a step-by-step process that is as mentioned below. Liquid Filling Machine Its Principles. The system is such that the powder bed is on one side while the empty capsule body is on the opposite side.

The soft capsule filling machine is added with pure water solid granules medical bone gelatin additives vitamins glycerin etc. NJP Series fully automatic hard capsule filling machine varies its output by varying die assembly quantity of die hole. A dosator machine with two.

By creating the FEC40 Fette Compacting has proven its innovative capabilities regard to the industrial capsule filling. Capsule filling machines should all have the following operating principles in common. Pharmaceutical processing is a series of steps and capsule filling is an important part of the process.

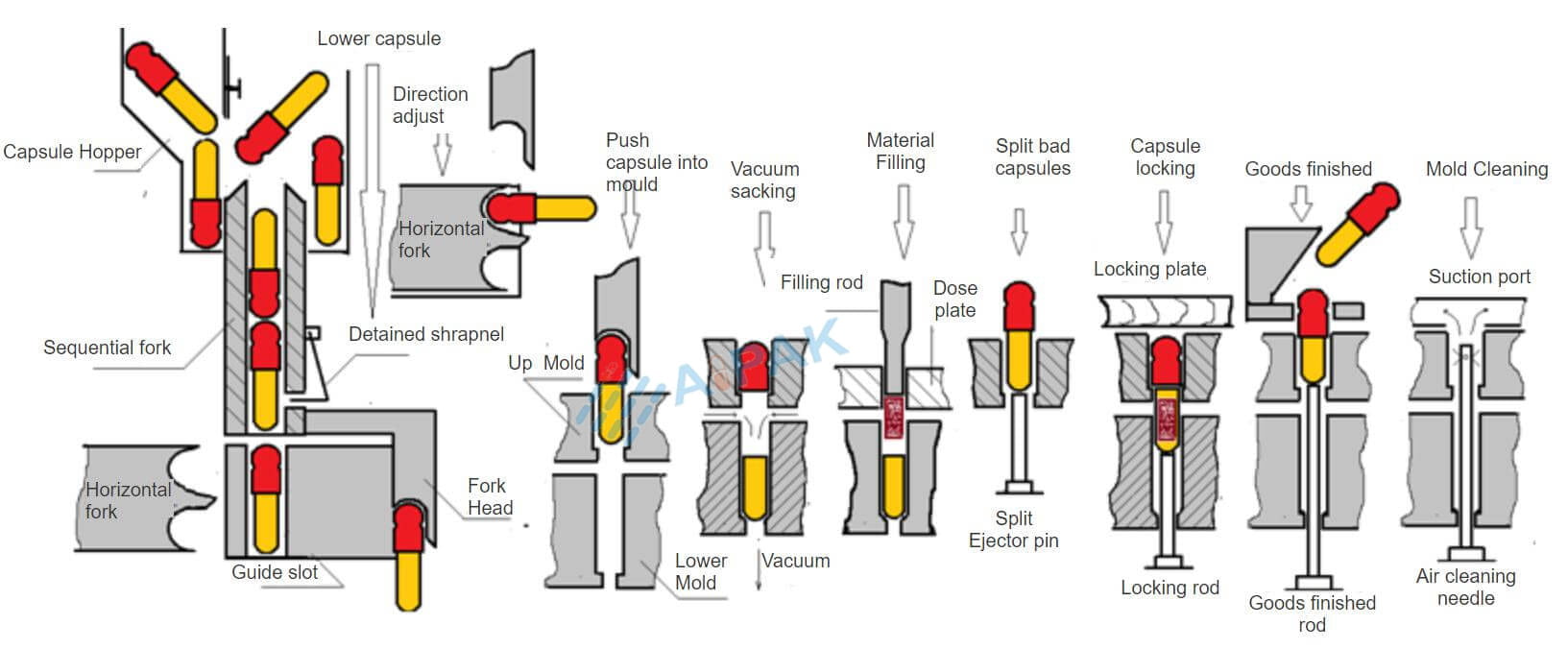

The main working principle of the automatic capsule filling machine is that when the machine is running the capsules in the capsule hopper will vertically enter the delivery fork one by one. First with the help of this component the product that is due for packaging is loaded with viscous liquid. Soft capsule filling machine through pre-treatment integrated ingredients adding pure water solid particle medical bone gelatin additives vitamins glycerin etc.

1 Empty capsules are discharged from the capsule hopper and pushed into position 1 sequencing station orderly by the push rod through the capsule tank. The capsule before sent for packing needs to be properly processed and filled with the help of a capsule Filling machine. Working Principles of Various Filling Machines 1.

It can be done by a number of different methods. The powders are transferred from one tamping punch to next to achieve a smooth finish. In the working principle of the bottle filling machine there is a cork accumulation tray.

But how does a process like this wor. Filling up the capsule body with pharmaceutical ingredients. Separation of capsule caps from bodies.

This can be done either manually or by means of an automated capsule filling machine. Working Principle of A Capsule Filling Machine. The powder here is compacted with the help of a tamping punch.

The system is such that the powder bed is on one side while the empty capsule body is on the opposite side. A dosator machine may have two segments. In short the working principle of a tamping type capsule filler involves a number of stages whose consistency and performance should be monitored.

The body of the capsule is transferred to the filling station where the active ingredients are filled in the capsule. Division of capsule caps from their bodies. Rectification orientation of the bad gelatin capsules.

Personal capsule filling machines is for small scale production and utilization. Rearrange the caps and bodies. The liquid filling machine works when the pressure is high.

On the other hand professional capsule fillers are used in pharmaceutical industries at large scale production with high efficiency. A dosator machine may have two segments. During the operation the capsules in the charging hopper at the first station are fed through two hoppers vertically to capsule-feeding plate one by one.

WORKING PRINCIPLE OF VISCOUS LIQUID FILLING MACHINE. Working Principle Of An Automatic Capsule Filler. It has 9 holes turning out a highest output of 1200 capsulesminute.

When the fork is sent down six capsules are delivered at a. At a certain ratio through the pre-processing comprehensive ingredients and stirred at a low temperature of 70 to 80 C The glue is evacuated after a period of time. Operating principles of a capsule filling machine.

In a certain proportion after 7080 C low temperature cycle mixing and melting after a period of time the gelatin is vacuumed. The working principle and operation method of the soft capsule filling machine. First the vacuum loader connects the capsule loading device to the capsule hopper and material loading port to the material hopper.

Medication filling. The capsules are rectified caps and bodies are separated active pharmaceutical ingredients API is filled wasted capsules are rejected capsules are.

10 Powerful Benefits Of Saintyco Dosator Capsule Filling Machine Saintytec

Filling Machines Their Working Principles

Capsule Filling Machine The Blueprint Guide Saintyco

Working Principle Of Dosator Type Capsule Filling Machine To Filling Powder Into Low Fill Weight Capsules

Automatic Capsule Filling Machine Working Principle Ipharmachine

Capsule Filling Machine The Blueprint Guide Saintyco

Automatic Capsule Filling Machine The Most Ultimate Importing Guide Capsule Filling Machine Your Best Online Resource About Capsule Fillers

Hard Shell Capsule Filling Machines Basicmedical Key

Automatic Capsule Filling Machine High Speed Capsule Filler

Automatic Capsule Filling Machine High Speed Capsule Filler

Hard Shell Capsule Filling Machines Basicmedical Key

Working Principle Of Dosator Type Capsule Filling Machine To Filling Powder Into Low Fill Weight Capsules

Automatic Capsule Filling Machine Njp Series Working Principle Ipharmachine

Powder Filling Drug Absorption Pharmacological Sciences

Working Principle Of Dosator Type Capsule Filling Machine To Filling Powder Into Low Fill Weight Capsules

Automatic Capsule Filling Machine Working Principle Ipharmachine